When failure is not an option - data centre chilled water pumps

Tue 13 Aug 2019

When failure is not an option

The temperature in a data centre needs to be carefully monitored and controlled, so it goes without saying that the chiller pumps must be reliable in order to keep the systems operational at all times.

During a recent routine service visit at a data centre on a dual pump “spill and fill” pressurisation and degassing unit with expansion vessels, the need for planned maintenance was never more apparent.

The equipment in question was a dual pump pressurisation and degassing unit with expansion vessels that is also backed up by an identical unit in the event of breakdown or servicing. The pumped system that is fed by this unit is for chilled cooling water which keeps the data halls cool.

The problem

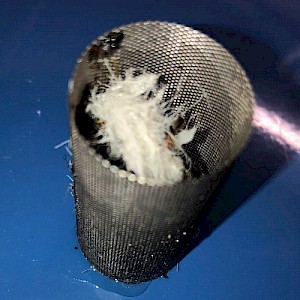

This equipment was relatively new and had been commissioned 6 months earlier. However, even after this short period of time, the filters were found to be severely blocked.

The filters are on the “spill” leg of the system which allow excess pressure from expansion to be returned to the expansion vessel. Expansion is likely to happen whilst a chiller is attempting to compensate for temperature increase whilst the associated pumps on the unit are used to return water to the system as expansion decreases when the temperature drops.

On this occasion, had these filters become totally blocked the system would have suffered over expansion and by design the monitoring controls would have caused the affected unit to shut down and the backup unit to take over.

However, in this case both units had a lot of debris in the filters,highlighting the importance of routine servicing from a skilled and knowledgeable engineer to identify and remove the debris before it becomes a critical issue.

So where does the debris arise from?

The system contains several thousands of litres of fluid – the expansion on the system alone can be up to 3000L. Even with system inhibitors there will always be particles in the mild steel welded pipework.

Debris such as thread sealing materials and other particles introduced from maintenance work may have been introduced after the initial cleaning and flushing. Likewise the system is also being added to with new circulator pumps etc as new data halls are built – if not thoroughly cleaned before introduction then there is an increased risk of contamination to the existing system.

Filters are not always installed, but on this occasion they were integral to the unit. They are quite compact and could easily be missed by someone without experience or consultation of the manual.

There are many different types and makes of this equipment and with the critical nature of the business, it is essential that any maintenance is carried out by experienced, expert and knowledgeable engineers supported by full operating and maintenance (O&M) instructions.

If you have critical equipment where failure is not an option, contact our service team on 0800 3317310 or email sales@pumpserv.co.uk

PumpServ is an independent distributor representing the major pump brands including Grundfos, Wilo, Xylem, Armstrong and Dab and is one of the top 3 independent distributors in the UK. The company has strategically located staff around the UK for the supply and servicing of commercial heating and chilled water pumps, pressurisation units through to waste water and drainage pumping stations across a wide spectrum of industries.

PumpServ provides a 24 hour / 365 days a year emergency breakdown service and expert staff are always available to help with enquiries and provide technical assistance.